What Does Mhs - Material Handling Supply Inc. Mean?

Table of ContentsThe Best Guide To Mhs - Material Handling Supply Inc.See This Report on Mhs - Material Handling Supply Inc.How Mhs - Material Handling Supply Inc. can Save You Time, Stress, and Money.Some Known Factual Statements About Mhs - Material Handling Supply Inc. The Only Guide for Mhs - Material Handling Supply Inc.

It's risky to spend in this devices if you can't scale your organization to the point that this financial investment is rewarding. Once your automated system is in area, you will not have much flexibility in your flooring area.

Like any machine, computerized tools can malfunction and even damage (https://www.slideshare.net/tannergraves23221). Breakdowns create downtime and held up all of your operations. You will need to determine the trouble quickly and fix it permanently prior to you shed also much cash, or worse, distressed your clients. Upkeep prices are another disadvantage of automated product taking care of systems.

The only way to stop this is to arrange routine upkeep on all components of the system. forklift rental athens, ga. It's not likely a person in your stockroom understands just how to do the job, so you'll have to employ a specialist or professional, which is costly. Lange-Lift makes all type of custom-made material handling tools, from scissor lifts to turntables and even more

Contact us today or have a look at more of our equipment in our item magazines. .

All About Mhs - Material Handling Supply Inc.

The most recent improvements in material taking care of systems help to satisfy the demands of countless firms that need taking care of tools. With the complex product handling procedures, having a sensible product taking care of system that adapts to the private demands of operators and industrial firms is a true benefit. The complying with are several of the advantages of using material carts and trains to move containers or unit loads from the stockroom to the construction site: Conserves moneyImprove securityLessen downtimeEnhance ergonomicsImprove efficiencyDecrease traffic on forkliftsExpand capacitySave spacePromote adaptabilityImprove the work environmentMaterial handling carts and trains are the biggest alternatives today, whether you are an assembler, production designer, logistic operator, logistics engineer, upkeep designer, safety designer, or administration head.

The continuous change to Market 4.0 and a smarter functioning or manufacturing environment is also depending on correct material monitoring. Using semi-automatic or totally automated remedies is the method to go here. The benefits of this material managing innovation include reduced downtime and faster just-in-time delivery and production.

Cranes and hoists are crucial components in various markets, playing a crucial duty in product handling and training procedures. Making sure the trusted and secure procedure of these makers is paramount. Normal upkeep of cranes and hoists provides a wide variety of benefits that directly influence security, efficiency, and the lower line of services that rely upon them.

The 7-Second Trick For Mhs - Material Handling Supply Inc.

Simply like any kind of other equipment, cranes and hoists have a limited life expectancy which is influenced by the type of usage. As a result, these equipments can stay in operation for many years, offering an outstanding return on financial investment.

This implies smoother and even more exact activities, which is essential in applications needing precision, such as production and building and construction. Properly maintained equipment also experiences fewer breakdowns, decreasing pricey downtime. Cranes and hoists take care of heavy tons and run in environments where safety is of utmost value as any kind of messing up of the tons can create loss of human lives along with assets under procedure.

The Facts About Mhs - Material Handling Supply Inc. Uncovered

Failing to adhere to these regulations may lead to penalties, lawful issues, and reputational damage. Normal upkeep makes sure that your equipment satisfies these requirements, aiding you stay compliant with sector requirements and policies. Downtime is the adversary of efficiency. Unexpected breakdowns or failures in crane and hoist systems can bring operations to a standstill.

Well-maintained cranes and hoists tend to be much more environmentally friendly. On a regular basis keeping your product managing tools can add to a greener and more sustainable future.

Expanding the service life of your crane and hoist devices is not just a sensible monetary choice however additionally important for preserving safety and security and functional effectiveness. Below are a number of ways to take full advantage of the longevity of your crane and hoist systems: Purchase detailed training for crane and hoist operators. Trained operators are less likely to abuse tools, leading to minimized deterioration.

Some Of Mhs - Material Handling Supply Inc.

It is vital during regular crane and hoist procedures. When a driver is relocating a lots, especially in scenarios where the marked area may be inhabited by another crane or setting up line workers, the danger of accidents increases significantly. Clear and continuous interaction is critical to make sure secure and reliable procedures.

Overloading a crane or hoist can speed up wear and potentially trigger tragic failings. Educate your crane drivers on the value of abiding by pack limits and supply clear tons ranking info for all devices (https://blogfreely.net/mhsinc30677/mhs-material-handling-supply-inc). Complying With OEM (Original Equipment Maker) guidelines carefully is critical, particularly taking into consideration that different crane and hoist versions may have one-of-a-kind demands requiring specialized focus

The standards develop risk-free functional practices by giving insights Get More Information right into load abilities, use strategies, and essential security preventative measures. They consist of detailed inspection timetables, lubrication demands, and detailed specs for the elements. These aspects collectively add to extending the tools's life-span, reducing downtime, and avoiding unanticipated malfunctions. Suppliers recommend the usage of authentic spare components and products for maintenance, preserving the devices's initial quality and performance.

Tia Carrere Then & Now!

Tia Carrere Then & Now! Susan Dey Then & Now!

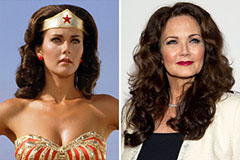

Susan Dey Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now! Bo Derek Then & Now!

Bo Derek Then & Now! Terry Farrell Then & Now!

Terry Farrell Then & Now!